Technology in FREYR Battery

The Technology department is responsible for the core of what FREYR is all about, namely the batteries themselves. Situated in the interface between the market and the factory, we are the ones that translate real-world needs into viable products. That means that we are involved in everything from research on new materials and production processes to battery systems engineering.

FREYR Technology is organized into several teams working in multiple locations. Although we are headquartered in Lysaker (close to Oslo, Norway), the department has also Technology hubs in Cambridge (USA) and Fukuoka (Japan), in addition to being co-located with all our manufacturing sites.

What we do

Lysaker is where the bulk of the management and engineering resources are located. This is where technology and product strategies are made, and concrete product development projects are started and led.

Our Product Design and Engineering team contains a mix of junior and experienced engineers with varied backgrounds ranging from chemistry and materials science, mechanical engineering, electrical engineering, to computer science, both from industry and academia. The team acts as a resource pool in product development projects and as technical sales support. This means interacting directly with potential customers and designing battery cell and module solutions for their applications.

Tasks involve electrochemical, mechanical, and systems design; requirements management; validation and certification; data analysis and modeling. All using a range of tools (Spreadsheets, CAD, Python, Matlab, COMSOL, and other software solutions).

A dedicated and growing Analytics group develops advanced models and analytics tools and assists product development engineers in data analysis and advanced modeling.

Innovation hub

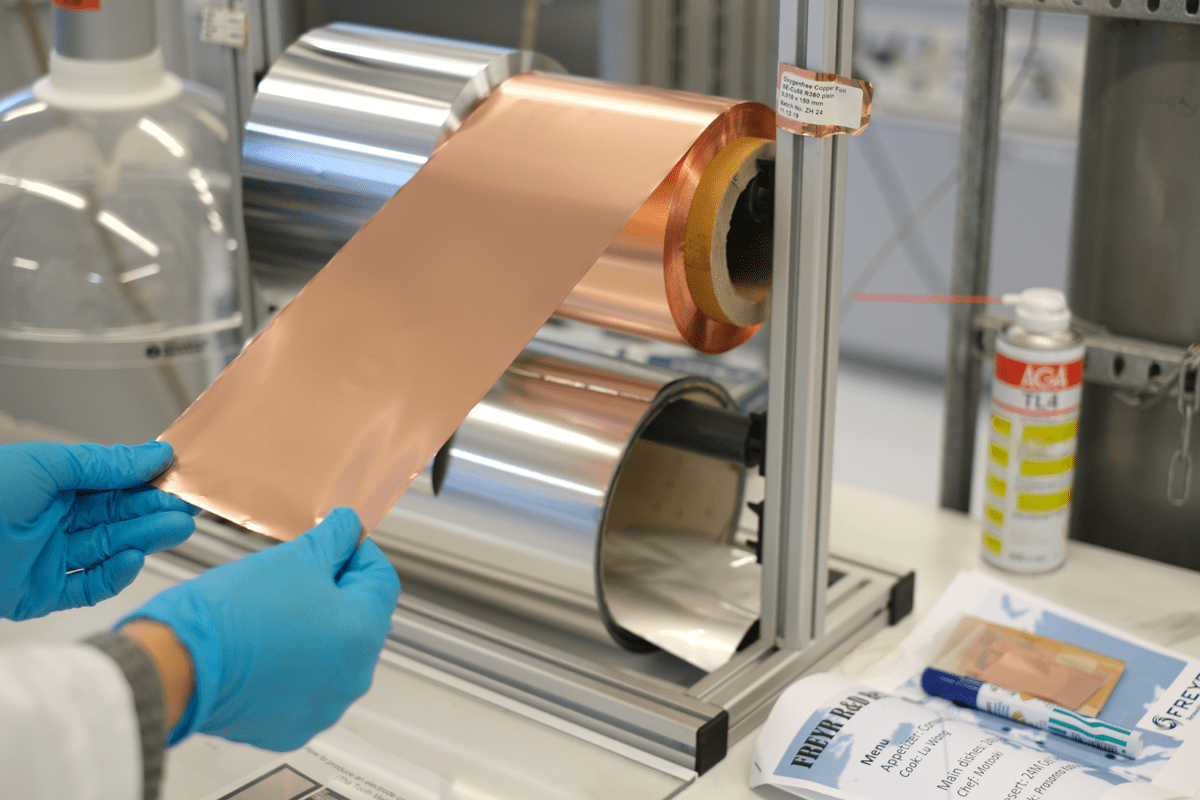

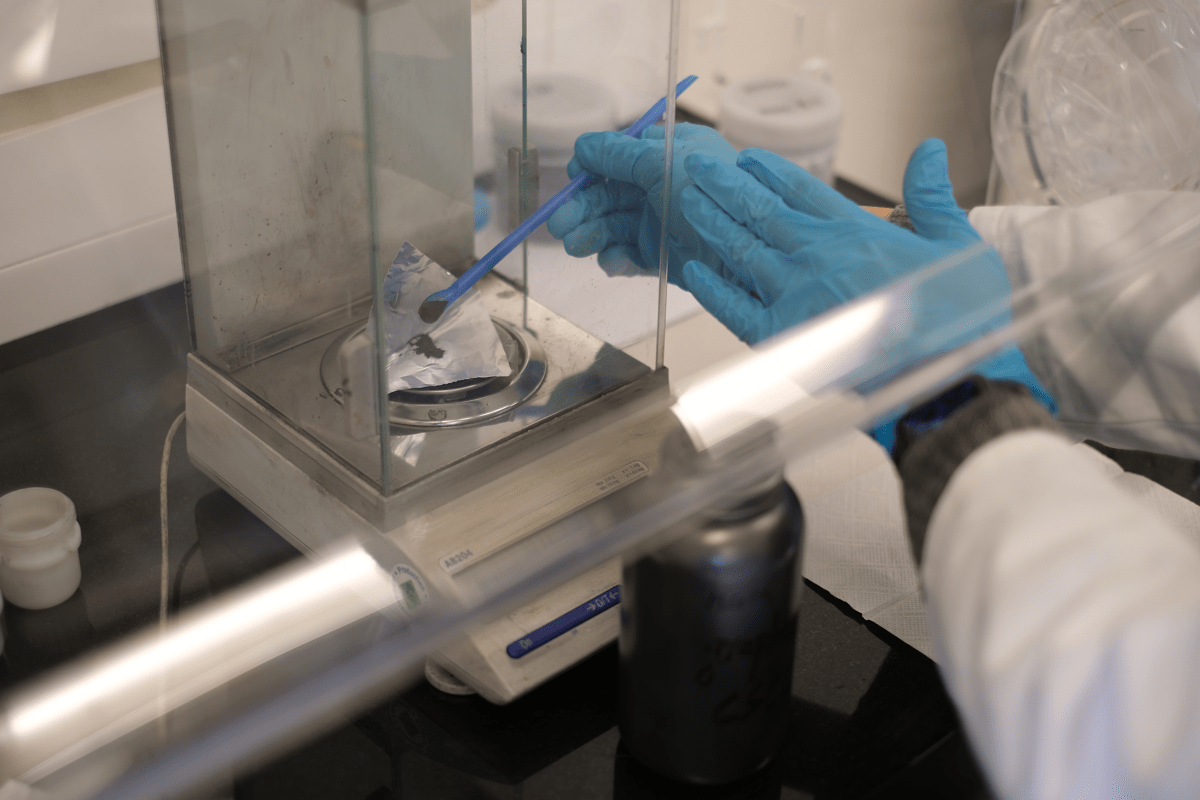

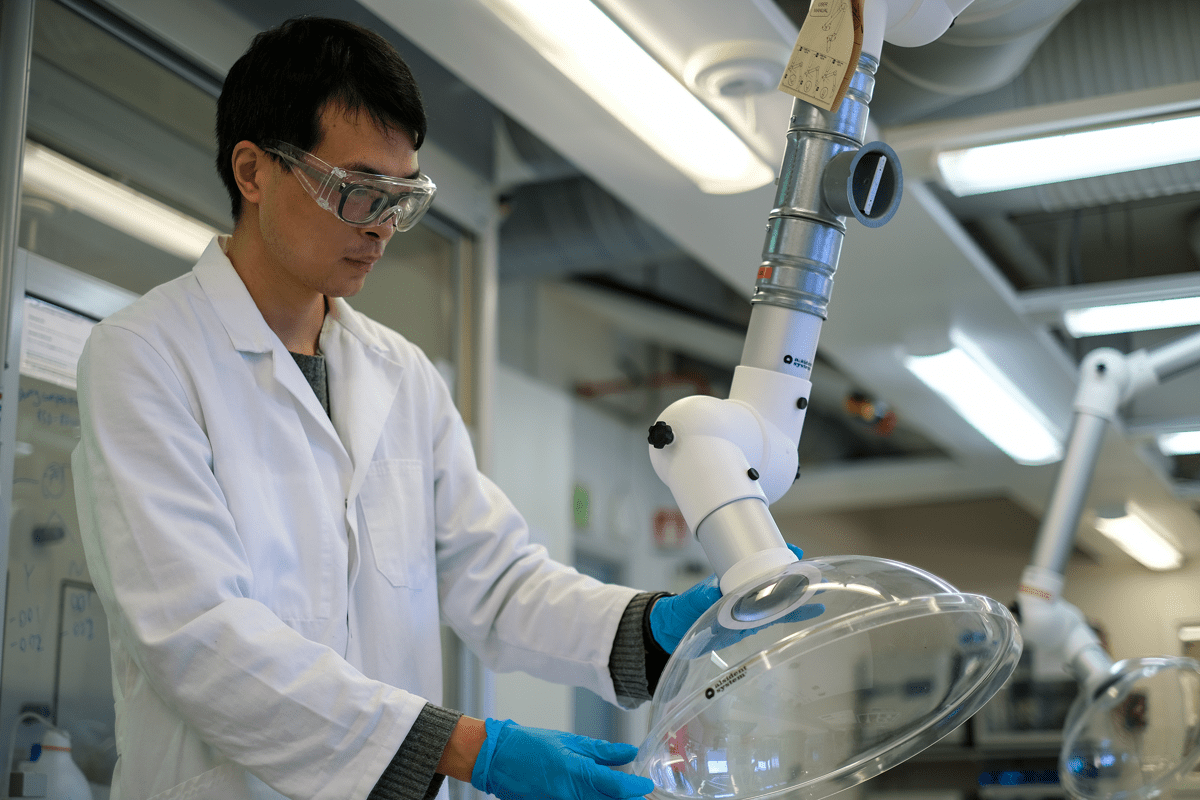

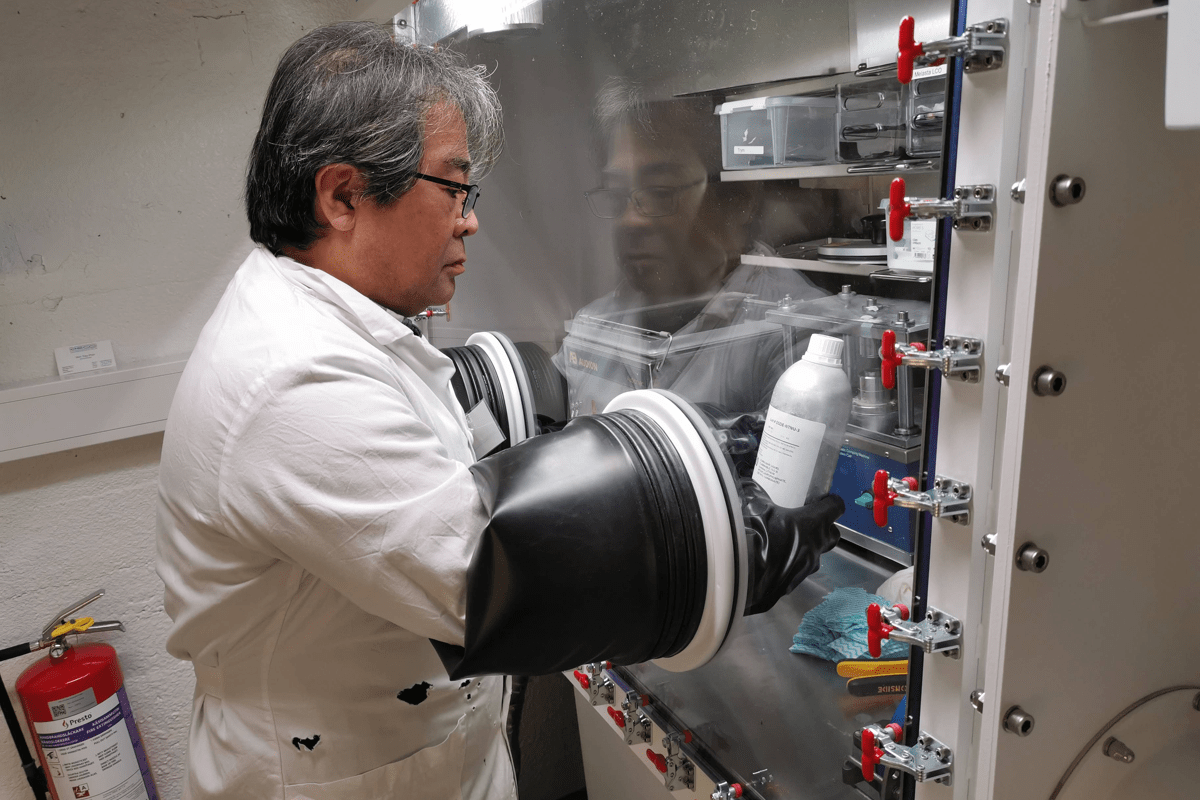

Our innovation hub in Trondheim (Norway) focuses on R&D work related to cell manufacturing processes and creates an interface between the technology and product development work, and the factory. Tasks include research into how to optimize the manufacturing process for different materials; how process parameters affect the final battery, and how to characterize intermediates in the production process. The team has access to a dry room, glovebox, and battery cyclers and, being situated in Trondheim, the team here is collaborating with and using equipment at the prominent research institutions NTNU and SINTEF.

Moving around in the company

We encourage people to learn by moving around the company, often through shorter or longer secondments. Several engineers have already gone both to the US and Japan for 3 month periods to work and learn in a different environment.

We are more open than most to transferring between departments. One example is an engineer getting into the nuts and bolts of production by transferring into our Customer Qualification Plant (commercially sized pilot plant) as a Process Engineer for a set time.

Japan

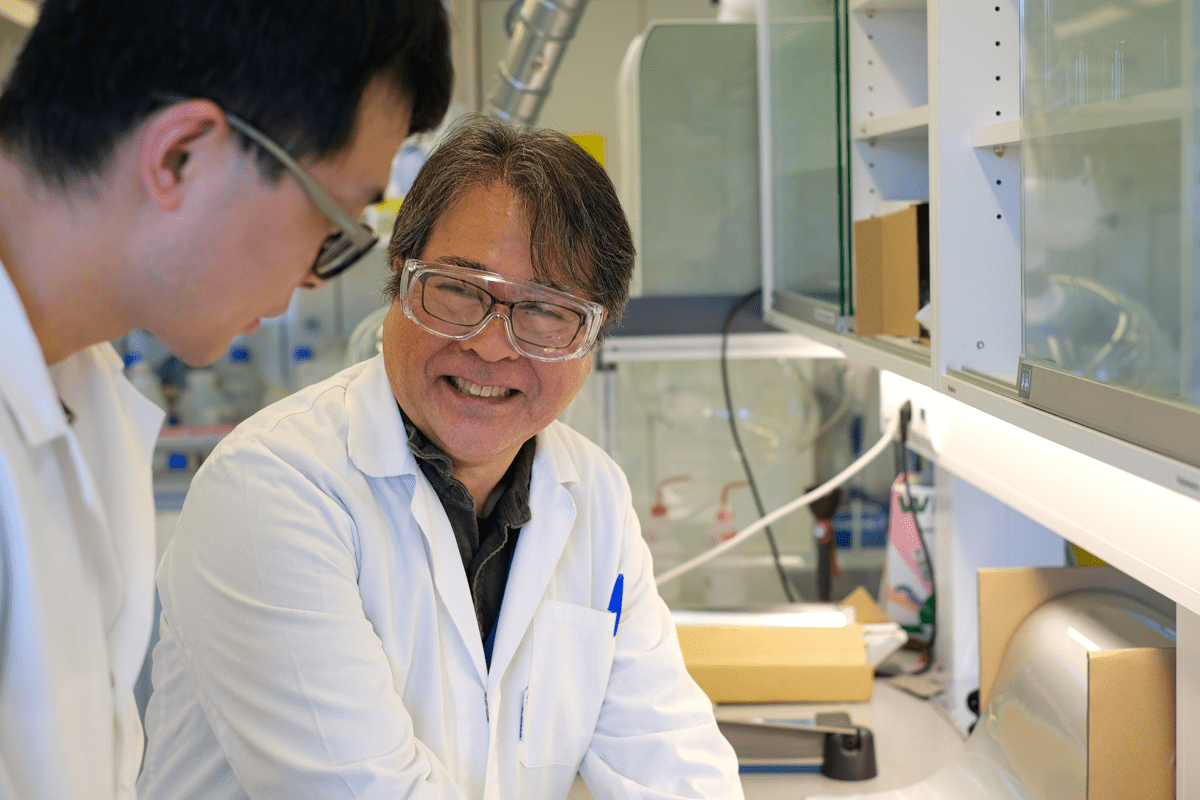

Our Technology hub in Fukuoka (Japan) does R&D on new raw materials. They make and test small handmade cells with different materials from different suppliers. They do the initial screening of performance and some optimization of the slurry. They work closely with the Supply chain and different suppliers to verify raw materials for our production process.

USA

Our Technology hub in Cambridge (USA) is tightly connected to our technology partner, 24M Technologies, an MIT spin-off that has its main lab and pilot facilities located there. Engineers located here work closely together with 24M partners, working with different samples together.

-

As an engineer in FREYR Technology, the power is in your hands to develop battery products that contribute to the global transition to sustainable energy systems.

Andreas Bentzen, EVP Technology

Explore

Technology team members have really interesting, meaningful work. If you are triggered by that thought, why not browse our material on our factories and automation, location, values, our approach to sustainability and the adventure that is FREYR?